At Synergetic, we want to give you an event you can be proud of. A/V has the power to elevate your event more than any other option.

It’s what ensures your auctioneer can be heard in the back of the room so you raise more money.

That a concertgoer in the last row has the same experience as someone in the front row.

And that your CEO walks on stage proud of the meeting they’re leading.

We know our clients want to look their best in front of their most important guests. That’s why we do what we do. And while a lot of that magic happens on site, much of it starts in our warehouse.

Behind the scenes: The Warehouse

Our 30,000+ square foot warehouse is where every event begins and ends. It’s where equipment is prepped, staged, loaded, and returned. It’s also home to our dedicated team of nine shop technicians—covering operations seven days a week—who make sure our on-site crews always have the gear they need.

Unlike other companies, our shop techs don’t split their time between prepping and running shows. Their sole focus is the warehouse. With 700+ events a year, that attention to detail is critical to keeping gear moving in and out efficiently and ensuring our clients get the experience they expect.

Our first shift starts at 7 a.m. and the last wraps at 6 p.m., keeping everything flowing from early morning through evening. 7 days a week.

The role of space

The most valuable asset in any warehouse is empty space. Without it, you can’t move cases, prep gear, or keep shows organized. That’s why our warehouse is carefully divided into departments—Audio, Video, Lighting, Rigging, and more—with dedicated areas for prepping outbound shows and receiving returned gear. Proper space management is what allows us to execute so many events each week.

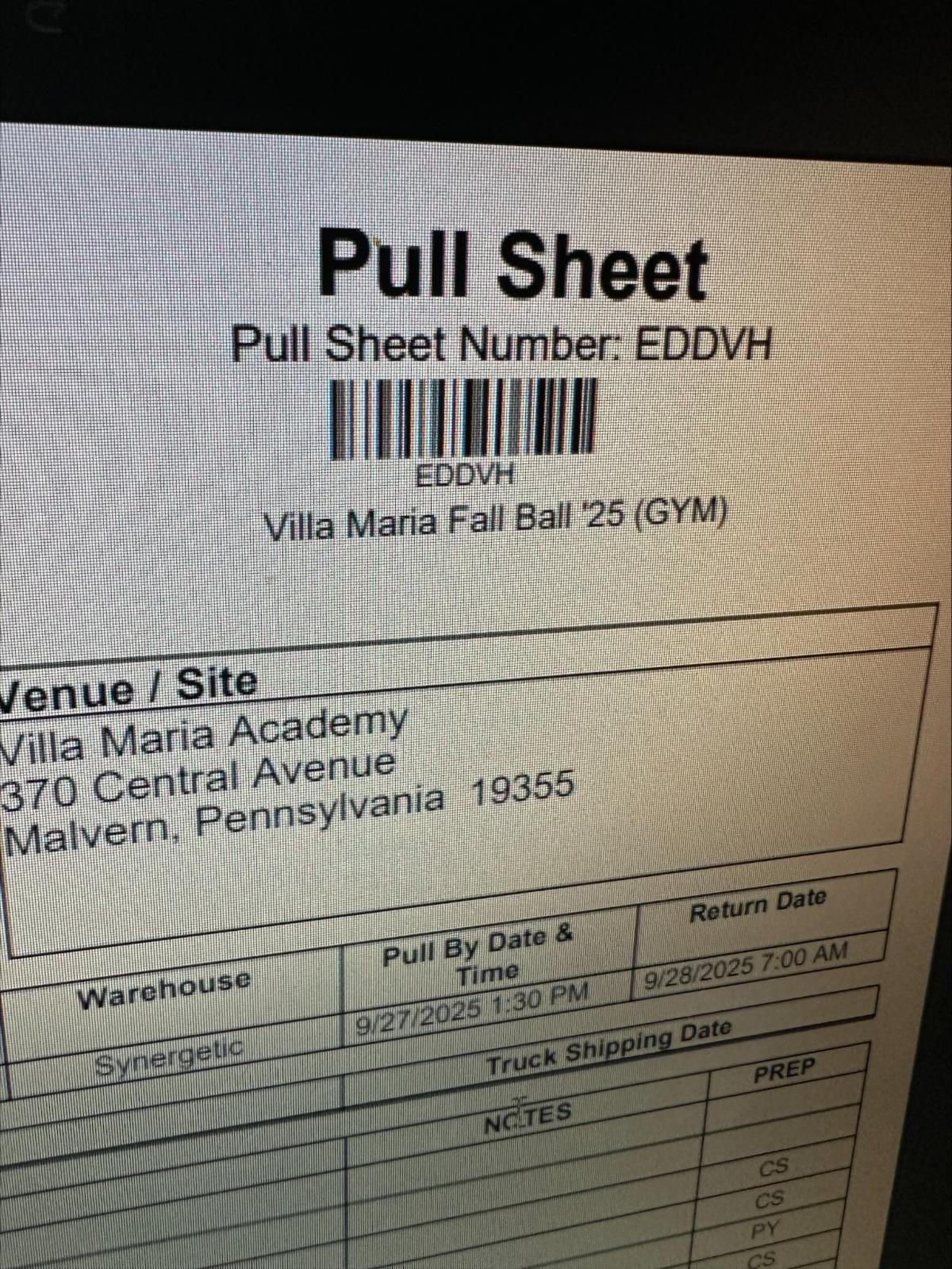

From pull sheet to truck

Every event starts with a pull sheet created by our Project Management team. Think of it as the script for the show—every single piece of gear is listed. Shop techs scan each barcoded item, move it to the prep area, and update the system in real time. Some shows take minutes to prep, others take days. Once the list is complete, the gear is staged and loaded onto the trucks.

When an event returns, the process happens in reverse. Everything is scanned back in, which lets us track missing items immediately—avoiding costly losses and keeping inventory under control.

A constant flow of trucks

In busy months like September and October, all six of our loading docks are in constant use. Trucks are being loaded and unloaded all day—one leaves, and another arrives hours later. The warehouse never really stops moving.

Quality control & repairs

With so much electronic equipment, quality control is key. We have a dedicated area for testing, maintaining, and repairing gear in-house. That means equipment goes back into service quickly, keeping us ready for the next event.

Ready for the unexpected

Because our shop is staffed seven days a week, we’re able to react quickly when clients need last-minute help. Maybe it’s an emergency add-on for an ongoing show, a forgotten lucite podium, or another production company in a bind—we can respond in real time.

The result

All of this behind-the-scenes work—the space, the systems, and especially the people—is what makes it possible for us to deliver consistent, flawless experiences on site. Our clients get the peace of mind that everything has been handled before the first guest even arrives.

September 30, 2025

September 30, 2025  Synergetic

Synergetic  About Us

About Us

August 23, 2025

August 23, 2025  Synergetic

Synergetic  About Us

About Us